Your One-Stop Custom Die Casting Manufacturer in China

- Rapid Prototyping → Functional Prototypes in 15 Days | Accelerate Your Product Development Cycle

- Engineering Support → From Design to Delivery, Our Engineers Optimize Your Part for Cost-Efficiency & Performance

- Eliminate Quality Audits → 0.3% Reject Rate Guaranteed with AI-Powered X-Ray Inspection

- Sustainable Manufacturing → Eco-Friendly Zinc/Aluminum Recycling | 95% Material Utilization Rate

- ISO9001:2015 & IATF 16949 cetificated die casting manufacturer

Precision Die Casting Manufacturer in China

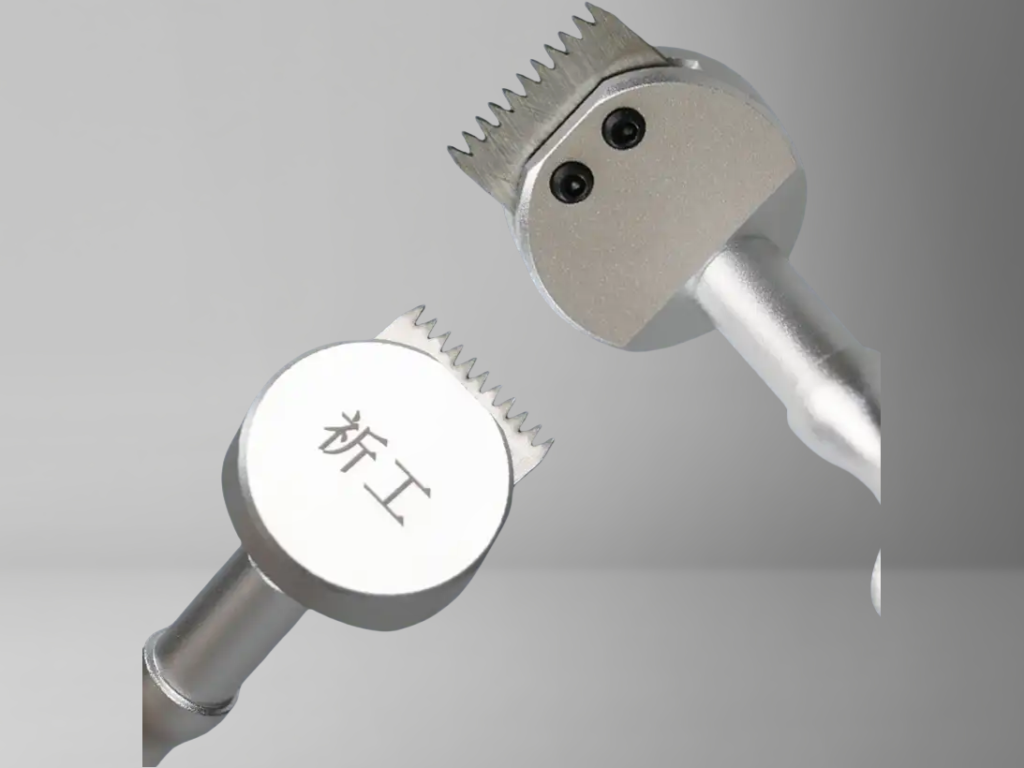

IEC MOULD is a professional die casting manufacturer in China, providing aluminum, zinc, magnesium, and brass die casting solutions for global customers. With integrated capabilities covering DFM engineering, mold design & manufacturing, high pressure and low pressure die casting, CNC machining, surface finishing, and assembly, IEC MOULD supports customers from concept development to stable mass production. Our die casting solutions are widely used in automotive, EV, lighting, industrial equipment, electronics, and hardware applications, where dimensional accuracy, mechanical performance, and long-term consistency are critical.

Services Provided by IEC Mould

Die Casting Material Consultation

Custom Design & Manufacturing(OEM & ODM)

Technical Support & Engineering Guidance

Precision Machining, Surface Treatment & Assembly

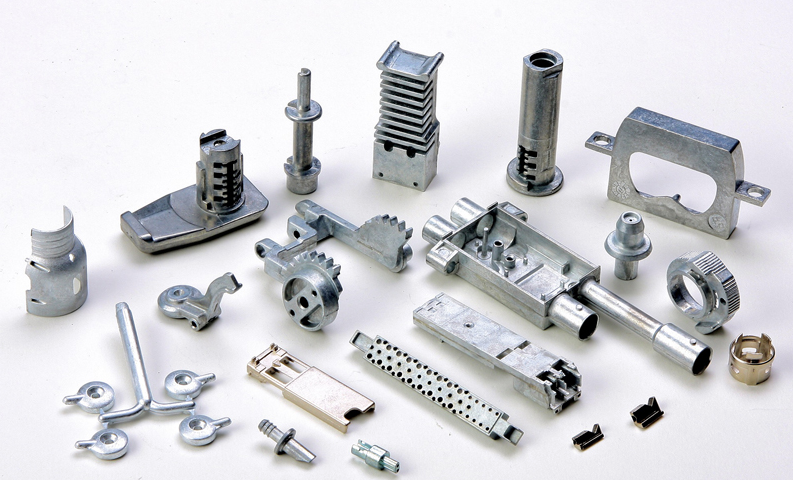

Our Die Casting Products

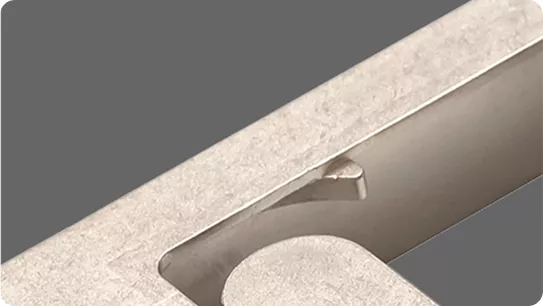

Aluminum Die Casting

- High pressure aluminum die casting

- Thin-wall and complex geometries

- Structural & load-bearing components

- Good corrosion resistance and machinability

- Good corrosion resistance and machinability

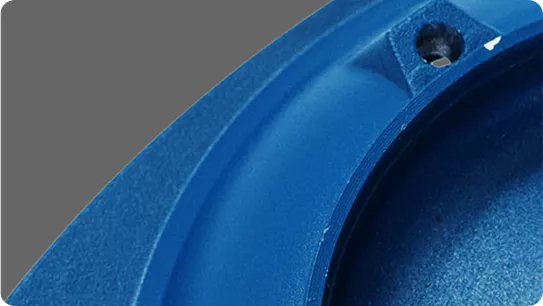

Zinc Die Casting

- Tight tolerances and dimensional stability

- Excellent surface quality

- Suitable for small to medium-sized components

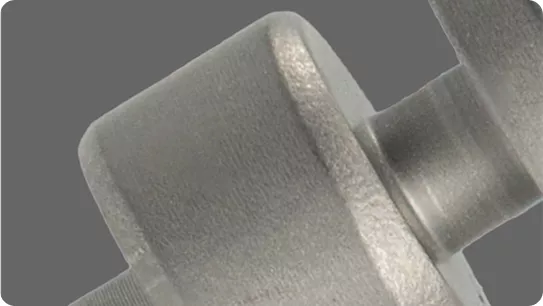

Magnesium Die Casting

- Low density and high strength-to-weight ratio

- Suitable for automotive, electronics, and portable equipment

- High pressure magnesium die casting process

Brass / Copper Die Casting

- Low density and high strength-to-weight ratio

- Suitable for automotive, electronics, and portable equipment

- High pressure magnesium die casting process

High Pressure Die Casting (HPDC)

- High production efficiency

- Excellent repeatability

- Suitable for medium to high volume programs

- Complex part geometries supported

Low Pressure Die Casting (LPDC)

- Improved mechanical properties

- Better material integrity

- Suitable for thick-wall or structural aluminum parts

- Commonly used for automotive and industrial components

Types of Die Casting Processes at IEC MOULD

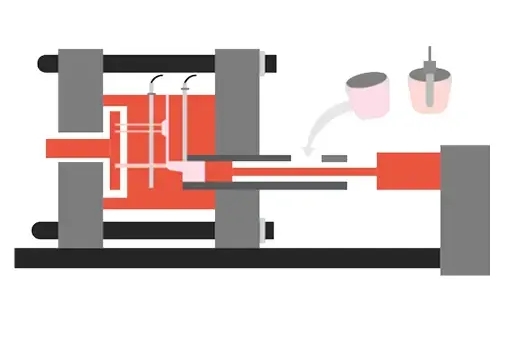

To support a wide range of project needs, IEC Mould provides three types of die casting machines, suited for different materials and deisgn complexities. We primarily apply hot and cold chamber casting. For components with tight tolerances and strong structural requirements, we offer advanced processes like semi-solid casting.

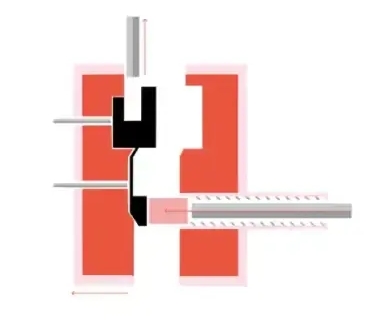

Cold Chamber Die Casting

Cold chamber die casting melts metal in a separate furnace before casting. The molten metal is poured into a cold chamber, where a piston pushes it into the die under high pressure. The process handles high melting point metals like aluminum. The separation prevents contamination and extends die life. This type of die casting produces car engine parts, aircraft components, and electronic housings where strength and precision matter

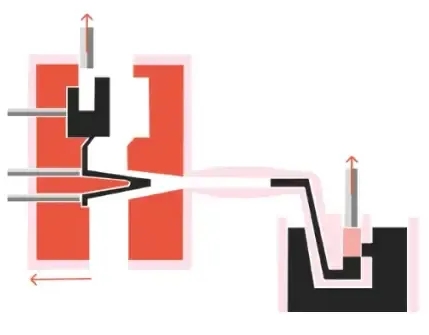

Hot Chamber Die Casting

Hot chamber, or gooseneck casting, connects the melting furnace directly to the casting machine. A piston pulls molten metal from the furnace and injects it straight into the die. This creates faster cycle times and reduces waste since the metal stays hot throughout the process. The process suits low melting point metals like zinc, magnesium alloys. The direct connection allows efficient high-volume production of toys, hardware, decorative items, and small mechanical parts.

Semi-solid Die Casting

Our Die Casting Factory Manufacturing Capabilities

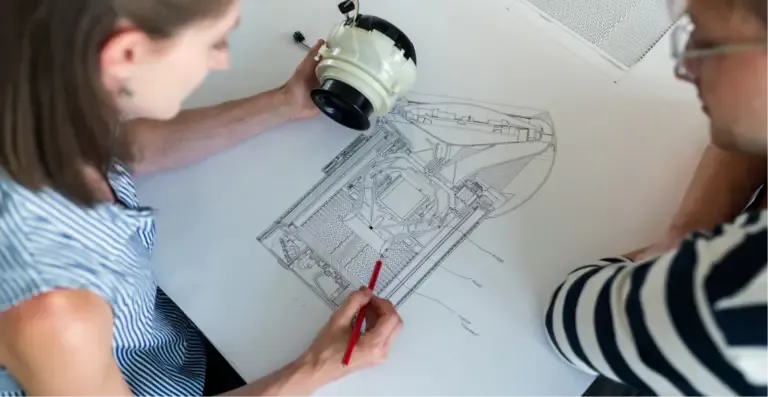

Die Casting DFM

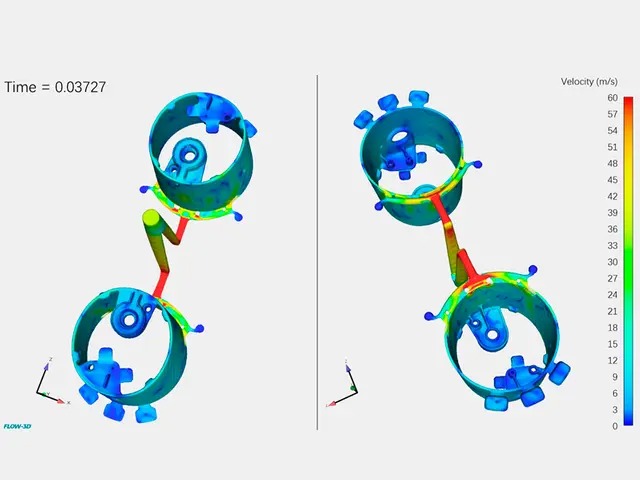

Die Casting MoldFlow

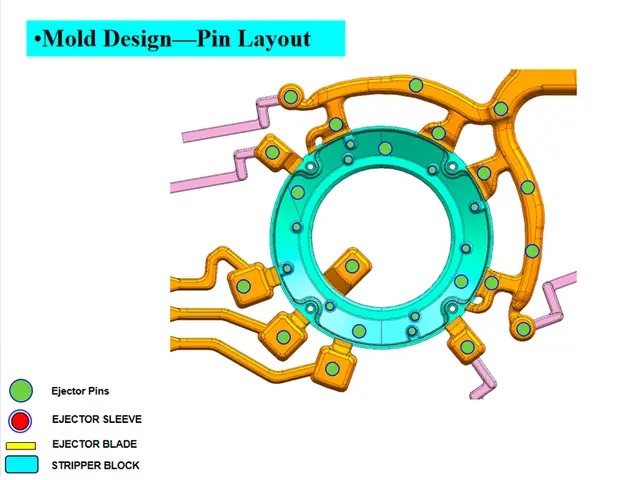

Die Casting Design

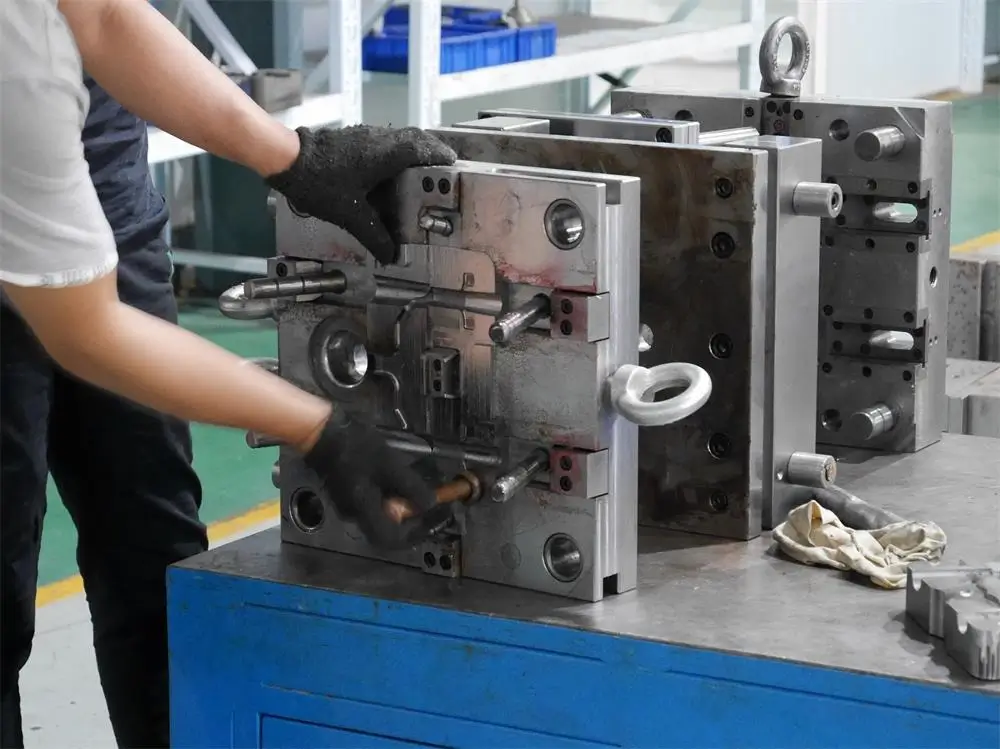

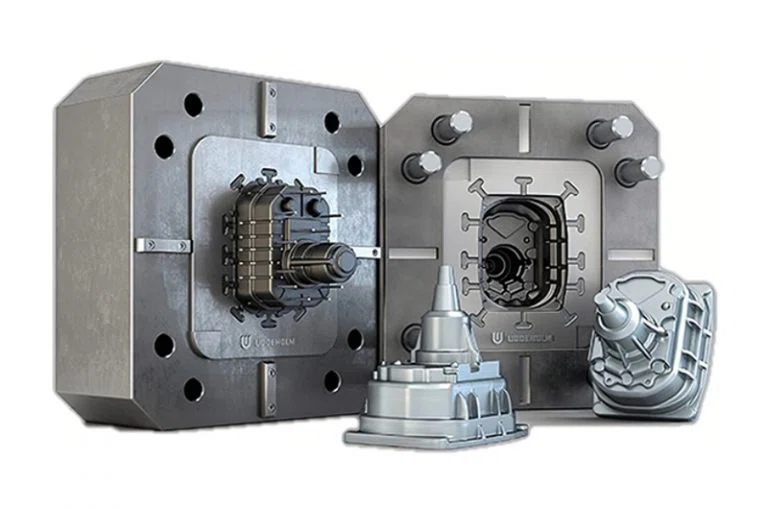

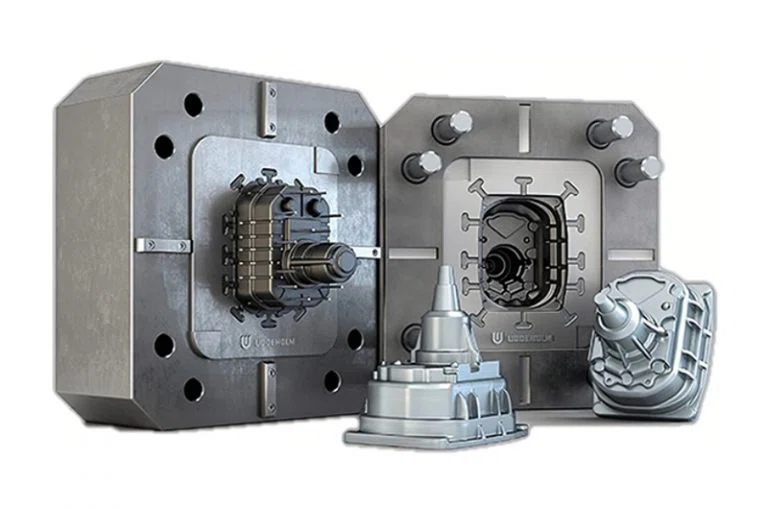

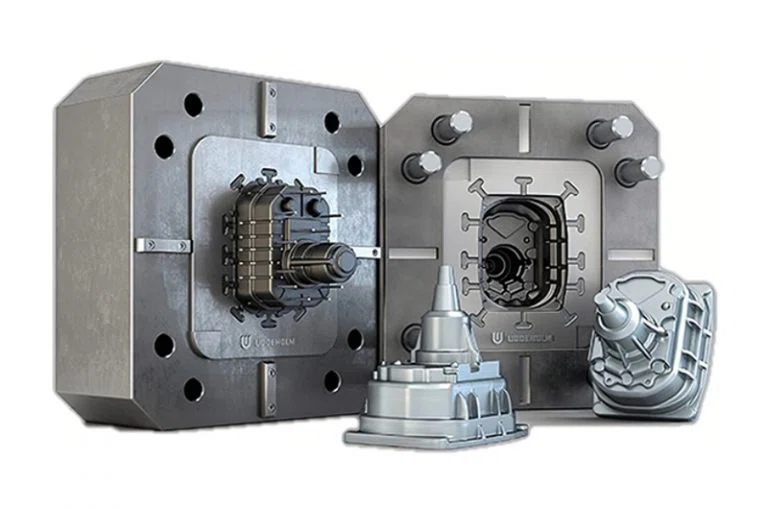

Die Casting Mold Making

Die Casting Productions

CNC Machining

Die Casting Finishes

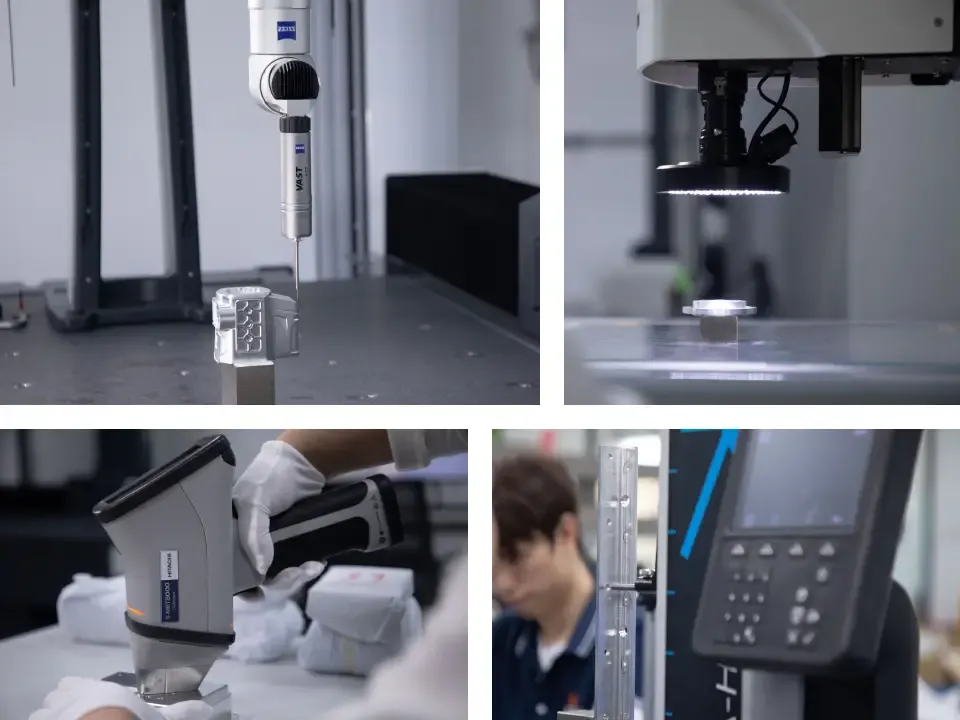

Die Casting Quality

Die Casting Materials & Finishes

Die casting tooling is manufactured from high-grade hardened steel to reliably withstand extreme temperatures, high injection pressures, and long production cycles. This ensures tooling stability, dimensional consistency, and extended mold life throughout serial production. For die casting parts, non-ferrous metals are primarily used due to their excellent fluidity, controlled solidification behavior, and relatively low melting points, which enable the production of complex, thin-wall, and high-precision components. While ferrous metals may be applied in limited or specialized cases, they are far less common in die casting compared to aluminum-, zinc-, magnesium-, and copper-based alloys.

IEC MOULD supports a wide range of standard die casting materials and also provides customized material solutions based on specific mechanical, thermal, and application requirements.

Tool Steel H13

Premium hot-work steel with high strength, toughness, and thermal stability. Maintains hardness and dimensional integrity under repeated heat cycles, ideal for aluminum and magnesium die casting molds with long production life.

Tool Steel 8407

Superior thermal shock resistance and higher toughness than H13. Better heat dissipation improves temperature stability and extends mold life, making it ideal for heavy-duty and long-run die casting applications.

Tool Steel 2344

Excellent high-temperature strength and resistance to thermal fatigue. Easy to machine and polish, delivering fine surface quality and dimensional stability—ideal for detailed and precision die casting tooling.

Zinc Die Casting

Excellent mold flow and dimensional accuracy make zinc die casting ideal for small, detailed components with tight tolerances. It is widely used in electronics, connectors, locks, and everyday hardware, offering a strong balance of mechanical strength and cost efficiency.

Common Zinc Alloys:

ZAMAK 2 · ZAMAK 3 · ZAMAK 5

Aluminum Die Casting

Lightweight and corrosion-resistant with an excellent strength-to-weight ratio, aluminum die casting enables the production of complex, thin-wall components with high dimensional accuracy. It is widely used in automotive, aerospace, and electronic applications where weight reduction, structural performance, and thermal conductivity are critical.

Common Aluminum Alloys:

ADC10 · A380 · ADC12 · Pure Aluminum · DM6 · HA6 · HA4 · 6063

Magnesium Die Casting

High strength with excellent machinability and natural EMI shielding, magnesium die casting is ideal for lightweight electronic housings, automotive components, and handheld device enclosures.

Common Magnesium Alloys:

AZ91D · AM60B · AM50A

Copper/Brass Die Casting

Known for excellent electrical conductivity, corrosion resistance, and mechanical strength, brass and copper die casting is well suited for electrical components, fittings, connectors, and functional hardware. These alloys are commonly selected for applications requiring durability, thermal performance, and long-term reliability.

Common Alloys:

Brass alloys · Copper-based alloys

Provides a functional finish with smooth surfaces and minor tool marks, ideal for non-cosmetic applications.

Enhances corrosion and wear resistance of aluminum parts while offering durable color options for improved appearance.

Protects aluminum and zinc die castings from corrosion and prepares surfaces for painting or coating.

Adds color and brand identity while providing extra protection against corrosion and wear.

Removes surface impurities and creates a uniform matte texture, improving paint or coating adhesion.

How We Control The Quality of Your Die Cast Parts

🔍 Material Assurance

We use only high-purity aluminum, zinc, magnesium, and copper alloys. All incoming materials undergo chemical analysis to ensure consistent quality.

⚙️ Process & Dimensional Control

Key die casting parameters—such as injection pressure, fill speed, & mold temperature—are strictly monitored. Finished parts are inspected using precision tools (e.g., CMM) to ensure dimensional accuracy.

🌧️ Corrosion & Defect Inspection

Coated parts are salt spray tested for corrosion resistance. X-ray inspections are performed on critical parts to detect internal defects like porosity or shrinkage.

🔩 Mechanical & Surface Testing

Each batch is tested for tensile strength and hardness. Surface quality is ensured through paint adhesion (cross-cut) testing and visual inspection during production.

Why IEC Mould is the Trusted Die Casting Supplier for 1000+ Global Clients

Decades of experience + automotive-grade certification ensure reliable solutions for complex designs (thin-wall/structural), enhancing product performance and reliability. Reduced project risk with guaranteed quality & compliance.

Secures stable supply for large orders while minimizing post-processing costs, boosting assembly efficiency, and ensuring end-product consistency. Mass-production capability + unmatched dimensional accuracy.

Leverage existing molds to slash tooling investment by 30% and accelerate new product launches to ≤15 days, capturing market opportunities faster. Faster time-to-market + significant cost savings.

Integrated design optimization, simulation, and rapid mold fabrication (±0.02mm) cut project timelines, enhance part manufacturability, and reduce management overhead. Seamless precision tooling + accelerated development.

Full-service capabilities—from casting to finishing—deliver production-ready parts, simplify your supply chain, and elevate product aesthetics/durability. Turnkey production + superior end-part quality.

Multi-stage verification using CMM (3D scanning), X-ray (porosity detection), spectrometer (material composition), and tensile testers ensures every part meets specifications. Prevents defects pre-shipment, reduces your QC costs, eliminates production downtime, and protects your brand reputation

Our overseas customers are from 30+ countries all over the world

Our advantages are reasonable prices, fast delivery, environmentally friendly products, quality assurance, and try our best to meet customer requirements for products.We look forward to the opportunity to cooperate with companies around the world, grow together, and succeed together. If you have any questions, please feel free to contact us.

Die Casting FAQ

What's the minimum wall thickness achievable in your die casting process?

Our high-pressure die casting achieves 0.5mm consistent wall thickness using vacuum-assisted technology, verified in automotive lighting and heat sink production

What’s your MOQ for new die casting projects

Tiered MOQ solutions:

• 50 pcs for prototype (modular molds)

• 1,000 pcs for production (shared tooling cost)

• 0 MOQ for strategic partners with annual contracts

What tolerances can you hold without machining?

As-cast tolerances: ±0.15mm/25mm for aluminum, ±0.10mm/25mm for zinc – view our tolerance class matrix.

How many cycles do your die casting molds last?

Our H13 steel molds with conformal cooling deliver 300,000+ cycles for aluminum, 1M+ cycles for zinc – 3X industry average.

Can you die cast parts with internal threads?

Yes. Our collapsible core tech produces M3-M24 internal threads in-die, eliminating 90% secondary tapping costs

Do you provide secondary operations after die casting?

Full in-house services: CNC machining (±0.01mm), powder coating, E-coating, ultrasonic cleaning & assembly.